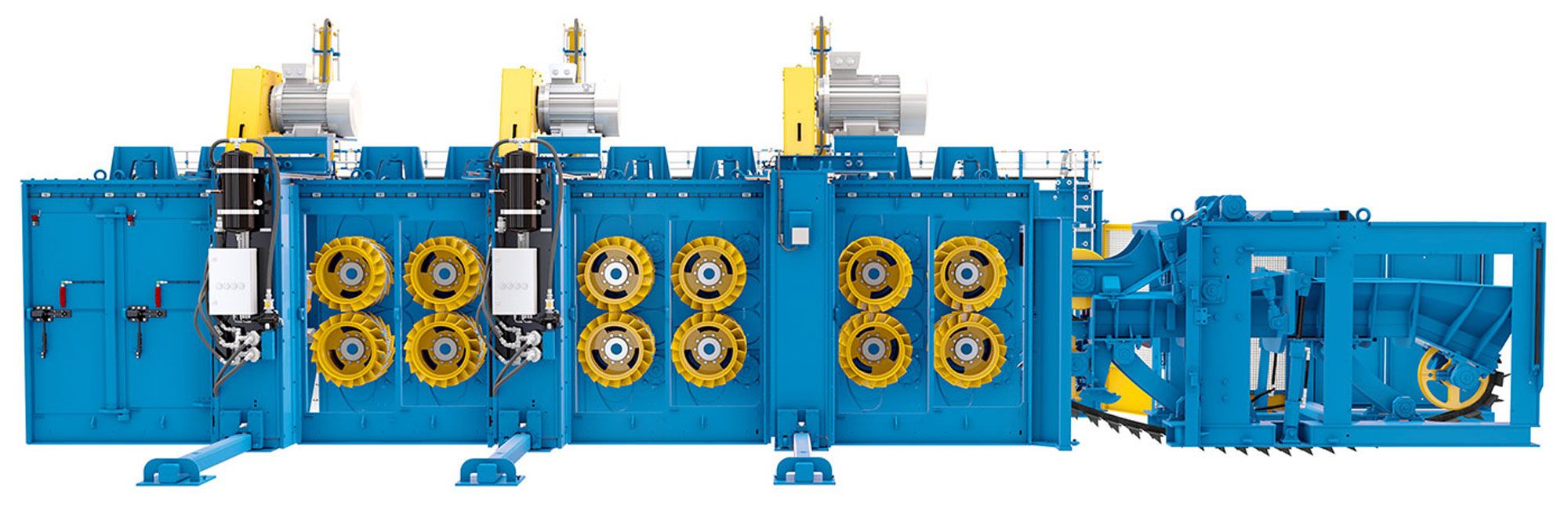

VK9000 Series (Heavy Duty)

Following our previous VK5000 and VK8000 series, the brand new VK9000 series is the latest and most robust debarker we have developed. It has a number of improvements that make using and servicing the debarker easier and safer than ever before. The VK9000 series debarker is primarily designed for mills using medium and large size logs.

With our famous heavy-duty trim, the VK9000 series debarkers are designed for modern large-scale production with high-speed debarking by using extra strong components as our standard, such as drive gears and drive shafts. Also, the VK9000 series features an updated machine frame for easier maintenance and enhanced working ergonomics. The renewed feedroll power transmission and pressure system are designed with the latest innovations in hydraulics and control systems used in the industry causing less mechanical stress on the machine and wood.

The newly designed modular construction of VK9000 series offers great flexibility to start the investment process with lower capital expenditure and build up the debarker as needs grow. The first stage of investment can be a single rotor machine. The machine can be extended by adding a butt reducing rotor and/or a second debarking rotor when higher speeds or cleaner chips are needed (VK Combi concept).

Features

-

Fully re-designed debarker frame, feedworks and feedroll hydraulics with strengthened critical components

-

Enhanced safety

-

Feedroll diameter 72 cm (28 ½")

-

Feedroll width 67 cm (26 ½") or 80 cm (31 ½") - is determined by size of rotor

-

Each driven feedroll has own planetary gear and electric motor - no belt or chain drives

-

Renewed hydraulic pressure system for feedrolls – rolls stay open when no log in between

-

Re-positioning of rolls before next log enters debarker - cylinders are equipped with Temposonic sensor

-

Feedroll hydraulic system with piston accumulators (nitrogen) - pressure level control as standard

-

Fixed debarking rotor – centering of logs with infeed conveyor

-

VK centering infeed conveyor in front of debarker as standard

-

Debarking rotor with pneumatic tool pressure system - four tool pressure levels to be chosen from control panel

-

Three rotor sizes 56 cm (22"), 68 cm (27"), and 81 cm (32") – always with six tool arms

-

Hydraulic rotor pull-out to service position as standard

-

Feedrolls with replaceable inserts (FibreMax)

-

Progressive grease lubrication system for points requiring constant/daily lubrication - lubricant flow control

-

Oil lubrication for rotor bearing, Air Seal and conveyor flite-chain

-

Oil collecting and recycling system available as option

-

Safety locks and safety sensors on service doors as standard

-

Service platform behind debarking rotor as standard

-

Service platform on debarker roof available as option

Benefits

-

Modular machine frame construction allows flexibility in investment planning (step-by-step)

-

Planetary gear with better efficiency generates less heat allowing higher feed speed in debarking

-

New hydraulic pressure system allows more accurate and quicker feedroll prestaging - less mechanical stress on debarker and wood

-

Wide feedrolls ensure smooth log feeding without risk of logs getting stuck

-

Piston accumulators (nitrogen) ensures boost for feedroll pressure – pressure level control improves machine reliability

-

Enhanced safety - all moving parts are inside machine frame or covered with safety guards - no need for additional protection

-

Centering VK infeed conveyor guides logs smoothly between feedrolls for minimal fiber loss in debarking

-

Air seal construction in debarking rotor enables remote control of debarking tool pressure and automatic tool opening when log feeding stops

-

Different tool tip versions ensuring optimal debarking quality in varying conditions

-

Extra wide tool tips allow higher feed speed

-

Hydraulic pull-out system of debarking rotor for easy maintenance

-

Enhanced working ergonomics - service platform opens when rotor is in out-position

-

FibreMax feedrolls with replaceable inserts with screwfastening for easy maintenance

-

Different insert types available ensuring grip in varying conditions

1-Rotor Machines with Pneumatic Tool Pressure

| VK9056HD | VK9056HDSL | VK9068HD | VK9068HDSL | |

|---|---|---|---|---|

| Debarking diameter (mm) | 100 - 560 | 100 - 560 | 100 - 680 | 100 - 680 |

| Min. log length (m) | 2.7 | 2.3 | 2.7 | 2.3 |

| Weight (kg) | 38,600 | 44,300 | 39,200 | 45,000 |

| Motor: rotor (kW) | 75 | 75 | 90 | 90 |

| Motor: feedworks (kW) | 22 + 5x11 | 22 + 6x11 | 22 + 5x11 | 22 + 6x11 |

| VK9081HD | VK9081HDSL | |

|---|---|---|

| Debarking diameter (mm) | 100 - 810 | 100 - 810 |

| Min. log length (m) | 2.7 | 2.3 |

| Weight (kg) | 40,200 | 45,900 |

| Motor: rotor (kW) | 90 | 90 |

| Motor: feedworks (kW) | 22 + 5x11 | 22 + 6x11 |

For technical details of Valon Kone Combi debarkers, please contact VK sales.